Manufacturing and Packaging

High Speed Production Lines Problems.............

Problem

Machinery and most mechanical motion move too fast for the engineer or maintenance technician to see. The typical response is to reduce the machine running speed to slow down the event to “see” what is going wrong. This of course changes the dynamics of the mechanical event (timing, bounce, vibration,oscillation, material interaction, etc.) and the problem goes away. Go back to normal run speed and the problem returns.

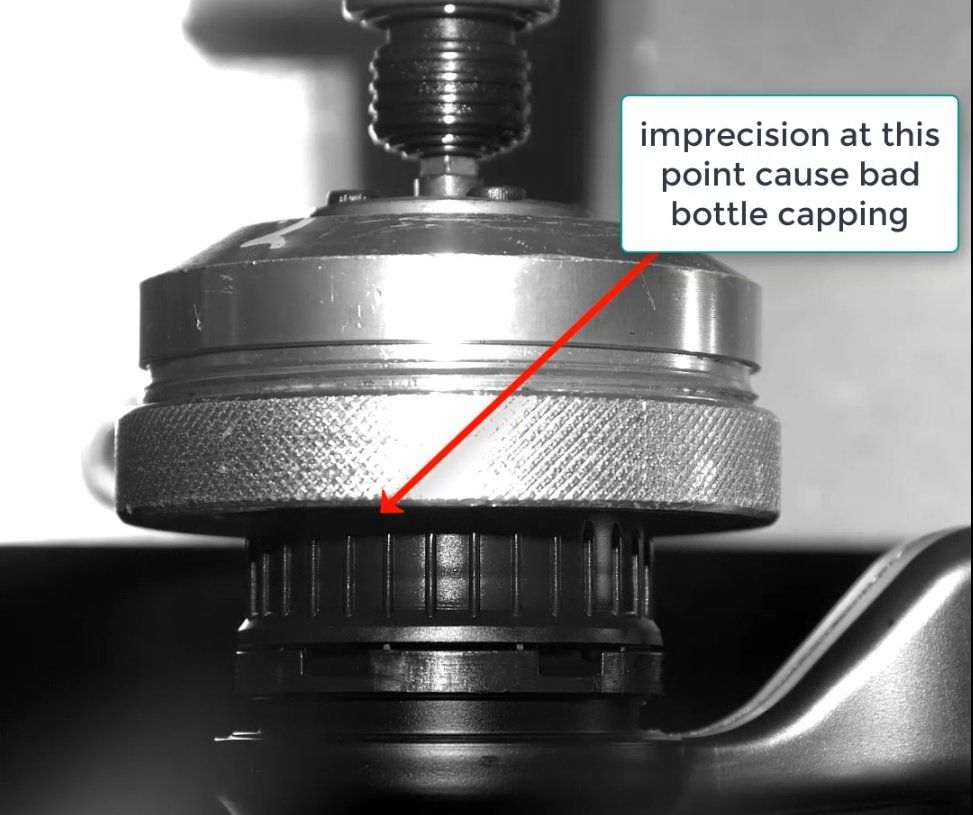

A defective process on one section of production line results in a finished product that is flaw and useless.

Solution

Using high-speed imaging to record the fast mechanical problems for instant slow motion playback allows the engineer to see, measure and understand motions, which are too fast for the human eye to perceive.

With high-speed video analysis, it is possible to examine various electrical and mechanical functions, timings and inter relationships defining the operation of the high speed machinery. Equipment designers, manufacturers and system end-users can all benefit from high-speed video analysis. The fine tuning of a system, after undergoing analysis, usually leads to higher productivity and less waste. This portable camera is ideal for factory manufacturing, maintenance and service. It helps to improve operational efficiency by reducing downtime and waste, increasing production capacity and improving product quality.

Portable PROMONSCOPE G2 system is a reliable high-speed camera with long recording time of 40 or 80 minutes for the monitoring of intermittent machine jamming and failures.