IR HIGH SPEED CAMERA

ENGINEERING

EXPERIMENTAL MECHANICS

Precise Stress and Impact Characterization.

Characterization of mechanical properties such as Young’s modulus, shear strain, viscosity and fracture toughness is very important in the development process of new alloys and composite materials. Researchers typically carry out many different measurements like tensile displacement tests, compression tests and fatigue tests using extensometer and split-Hopkinson bars setups. Infrared imaging allows to characterize the energy released by the investigated material as it undergoes elastic and plastic deformation up to the fracture point.

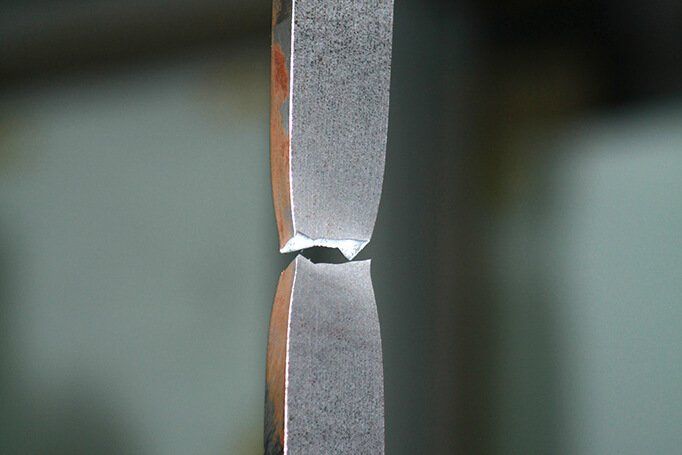

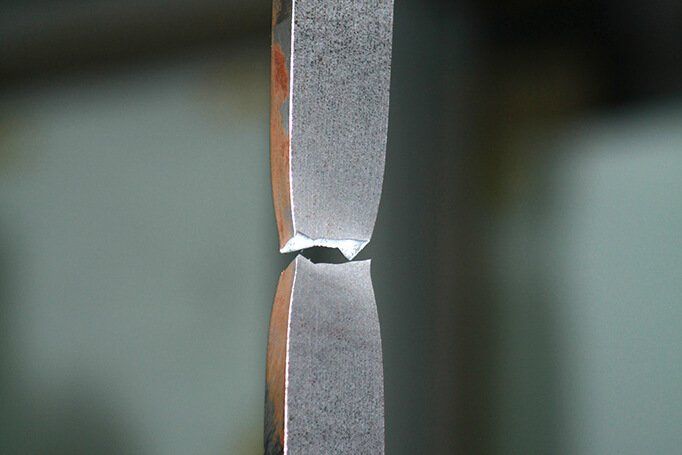

Tensile testing of a steel rod observed in infrared using Telops’ FAST M2k. Video courtesy of University of Waterloo, Canada.

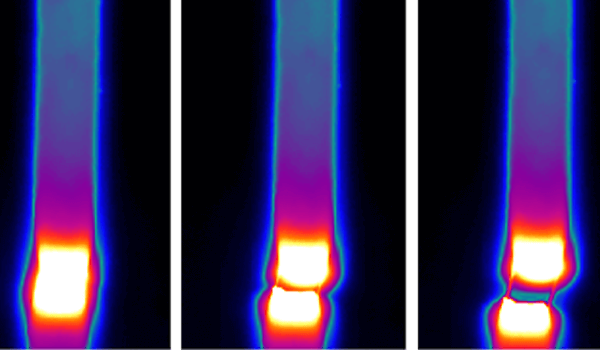

Tensile testing of a composite material observed in infrared with a Telops’ hd camera. Video courtesy of University of Waterloo, Canada.

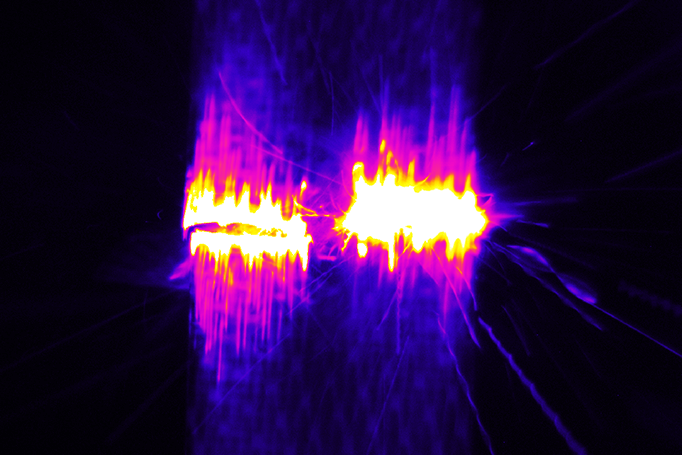

High-Speed Infrared Imaging of a Split-Hopkinson Pressure Bar Experiment.

Video courtesy of the Structural Impact Laboratory (SIMLab) of the Norwegian University of Science and Technology (NTNU).

ADDITIVE MANUFACTURING

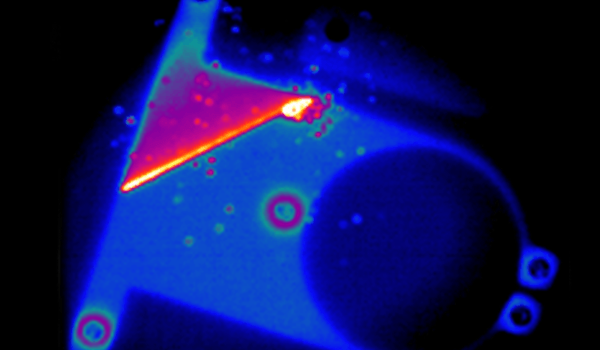

High-Speed Infrared Imaging of Metal Parts Fabrication by Additive Manufacturing.

High-speed infrared imaging provides new insights for research on additive manufacturing. Fundamental research on heat transfers and monitoring of the printing process can benefit from high spatial, thermal and temporal resolutions. Here, Argonne National Laboratory uses infrared imaging (left), as well as X-ray diagnostics (right) to prevent defects during additive manufacturing processes. X-rays offer insight into the microstructures of the meltpool, while infrared imaging – provided by a Telops M3k at 100 000 frames per second – allows to visualize the formation of plumes of vaporised powder that form when the laser hits the material. These high-temperature plumes inhibits the efficiency of the laser. To learn more, read this blog post. Animated images courtesy of Argonne National Lab.

NON-DESTRUCTIVE TEST

Thermal Patterns of Defects.

The presence of cracks and defects changes the thermal properties of materials. Infrared imaging provides unique insights for remote inspection of various objects such as electronic components and artworks where non-contact analysis is more suitable. The correct interpretation of thermal flows can reveal the presence of structural changes within the material and prevent failures.

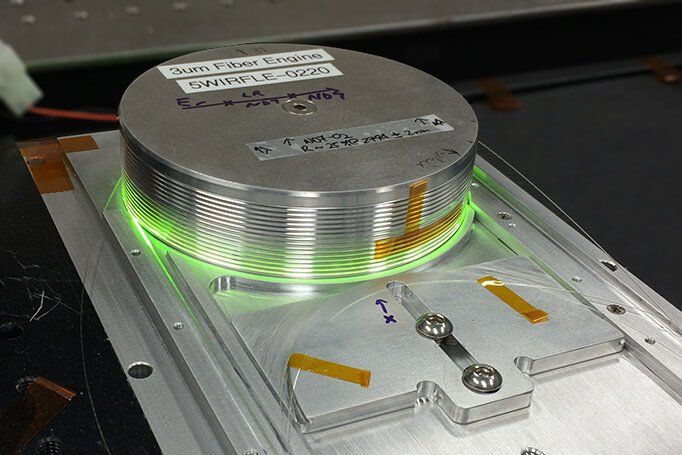

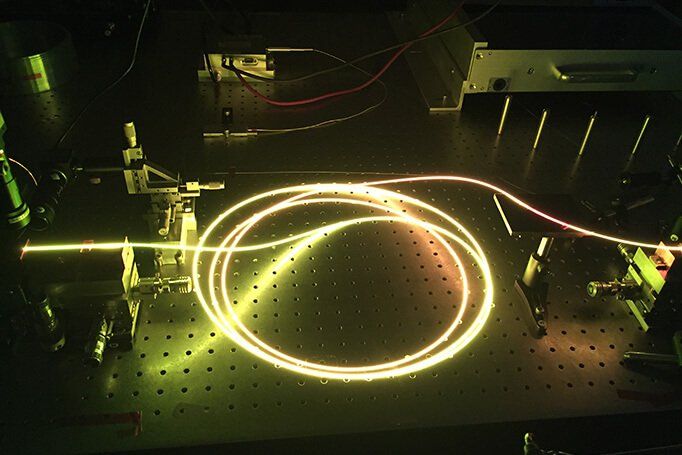

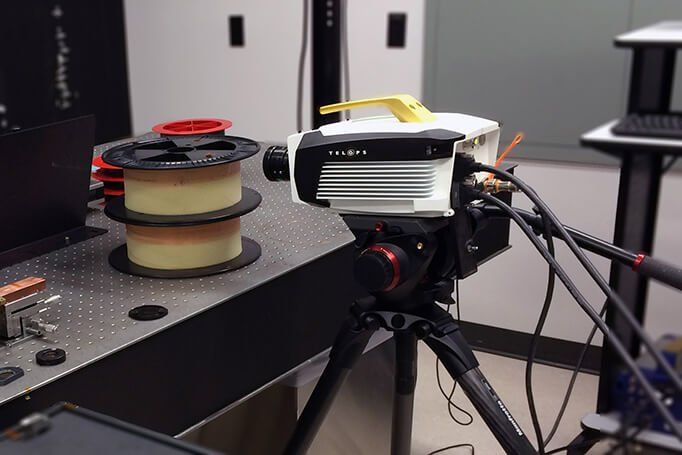

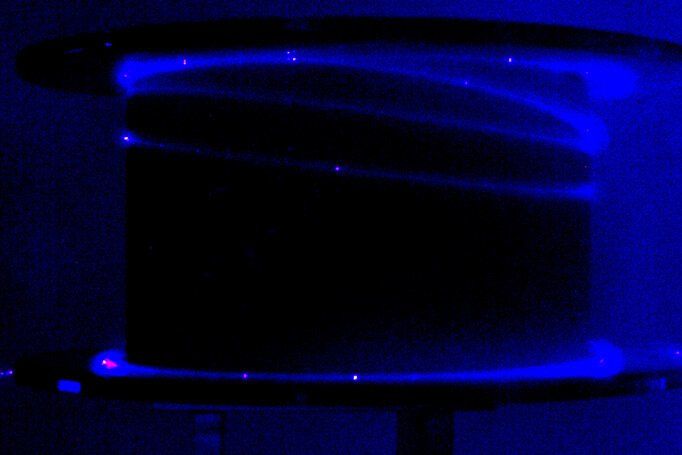

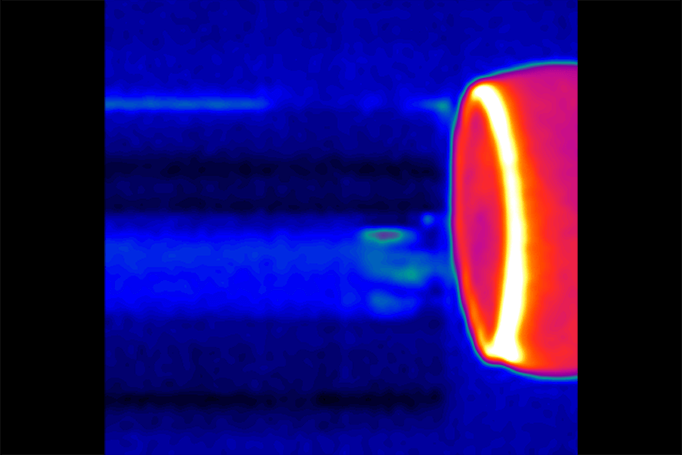

Detection of Defects in Laser Fibers.

By launching a mid-infrared laser signal in a fiber core and recording its side scattering with a wide spectrum infrared camera, scientists are able to screen optical fibers for defects – an crucial step in the development of high-power infrared lasers. Images courtesy of Université Laval, Quebec, Canada.