Seattle Safety leads the global market in destructive and non-destructive vehicle crash testing systems with advanced technology and a full spectrum of products and services. Headquartered in Auburn, Washington, the company began designing and supplying crash testing equipment in 1996, primarily to the automotive and aerospace industries.

Since the launch of the ServoSled in 2002, Seattle Safety has been enhancing the performance of crash testing safety labs around the world across a wide range of applications that include occupant safety systems, bio-mechanical research, and vehicle structure testing. We have installed more than 90 systems for a variety of customers worldwide. Seattle Safety is dedicated to providing top-of-the-line, flexible testing solutions in order to improve vehicle safety, prevent occupant injury and save lives. We’re ready to support you with a complete systems approach, expert systems integration and hands on training.

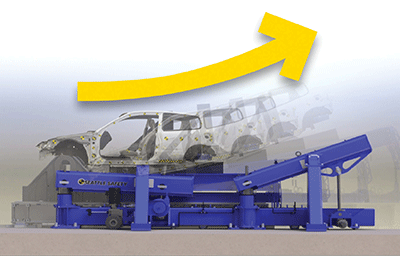

ServoSled™ Catapult Sled Systems

The premier choice of automotive safety labs worldwide

For the highest productivity and optimal performance in the lab, ServoSled™ leads the market. Efficiently and accurately test everything from low-g whiplash to high payload crashes.

Comply with the all of the latest FMVSS, ECE, and NCAP safety standards. The system’s innovative technology offers a number of key advantages to help lab managers meet the demands of safety engineering.

ServoSled™ 1000

Cost-Effective solution for component-level testing

The ServoSled 1000 performs seat, child seat, seatbelt, and battery regulatory pulses as well as more complex frontal vehicle pulses. Built on the proven ServoSled technologies being used in more than 50 safety labs worldwide, the ServoSled 1000 can provide reliable, repeatable compliance test performance.

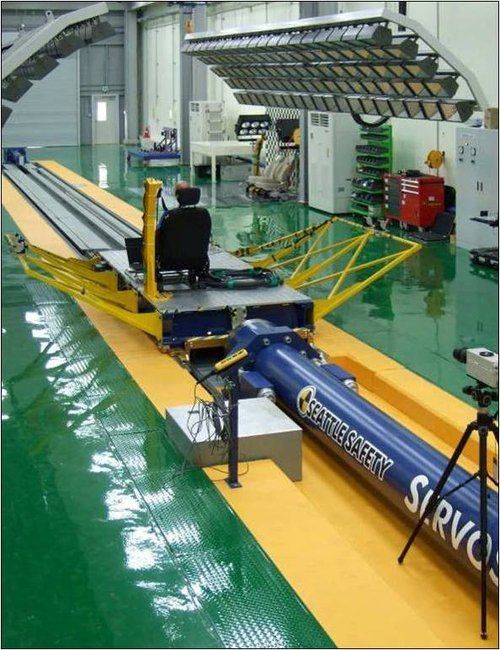

Decelerator Sled Testing System

The highest overall performance of any decelerator sled available at any price

The advent of automobile safety regulations in the 1960’s created demand for devices that could economically and accurately assess the performance of safety restraint systems without requiring the destruction of a vehicle. Sled systems to assess safety restraint components can either be decelerator type, where the sled is gently accelerated to an impact velocity and then stopped in a controlled manner, or reverse acceleration, with the physics reversed.

Dynamic Pitch Simulator

Add the ability to simulate pitch on your existing sled

The Seattle Safety Dynamic Pitch Simulator is an economical add-on accessory to sled test systems. Current lab managers can add pitch simulation without replacing their systems, and new customers can buy with confidence knowing they can add the simulator any time in the future.