IR Camera for Research, Science and Engineering

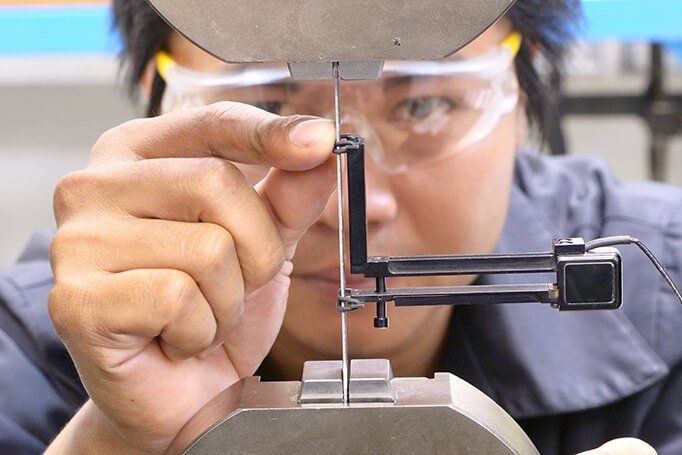

Experimental Mechanics

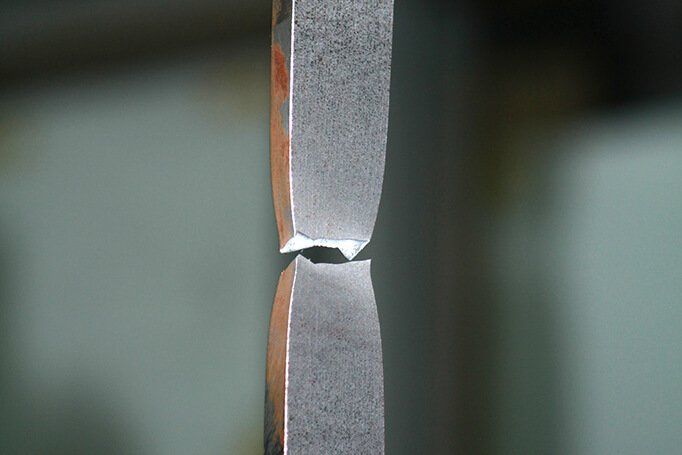

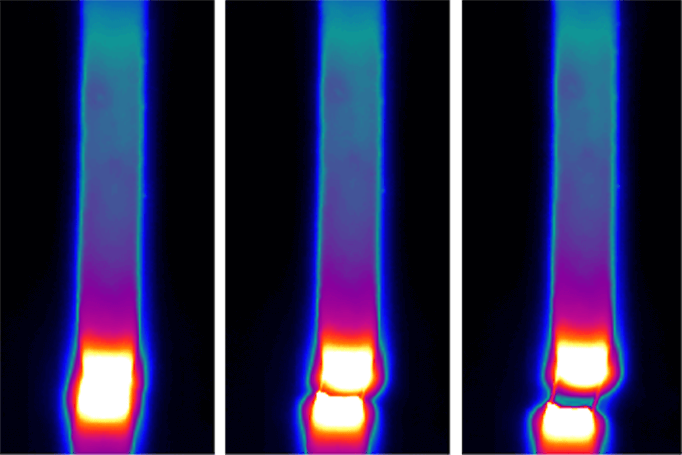

- Characterization of mechanical properties such as Young’s modulus, shear strain, viscosity and fracture toughness is very important in the development process of new alloys and composite materials. Researchers typically carry out many different measurements like tensile displacement tests, compression tests and fatigue tests using extensometer and split-Hopkinson bars setups. Infrared imaging allows to characterize the energy released by the investigated material as it undergoes elastic and plastic deformation up to the fracture point.

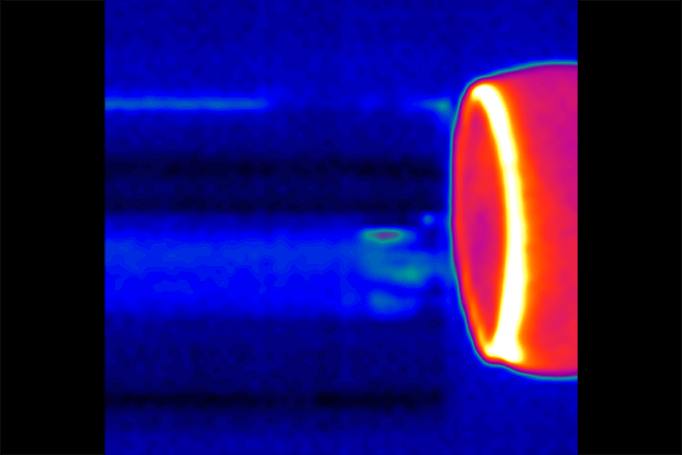

Combustion Analysis

- Most combustion reactions generate infrared-active gases such as carbon dioxides (CO2) and water vapor as well as known pollutants like carbon monoxide (CO) and nitrogen oxides (NOx). On this regard, infrared imaging represents an interesting diagnostic tool as it allows chemical imaging and temperature measurement at the same time. High-speed infrared imaging is useful for characterizing fuel injection, ignition and combustion in internal combustion engines (ICE), gas turbines or jet engines, regarding which lowering fuel consumption and soot generation represents an important research aspect.

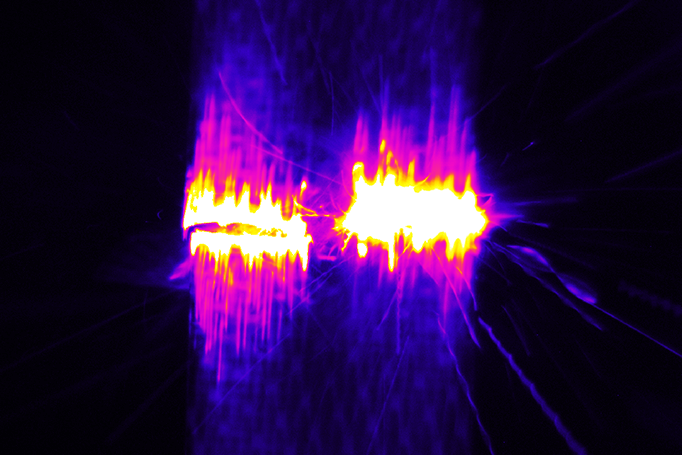

Experimental Mechanics

Tensile testing of a steel rod observed in infrared using Telops’ FAST M2k. Video courtesy of University of Waterloo, Canada.

Tensile testing of a composite material observed in infrared with a Telops’ hd camera. Video courtesy of University of Waterloo, Canada.

High-Speed Infrared Imaging of a Split-Hopkinson Pressure Bar Experiment. Video courtesy of the Structural Impact Laboratory (SIMLab) of the Norwegian University of Science and Technology (NTNU).

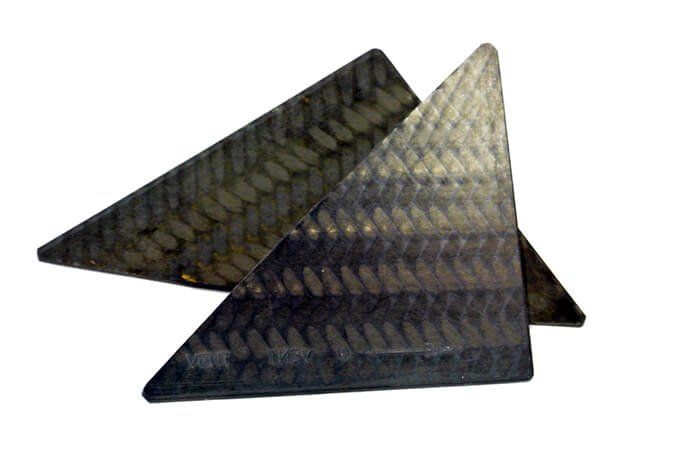

Projectile impact observed on a composite material plate.

You need an infrared camera, but you are unable to find one that meets your needs? No need to compromise. Please let us know what you are looking for, and our team of experts will find the best solution customized for your application.